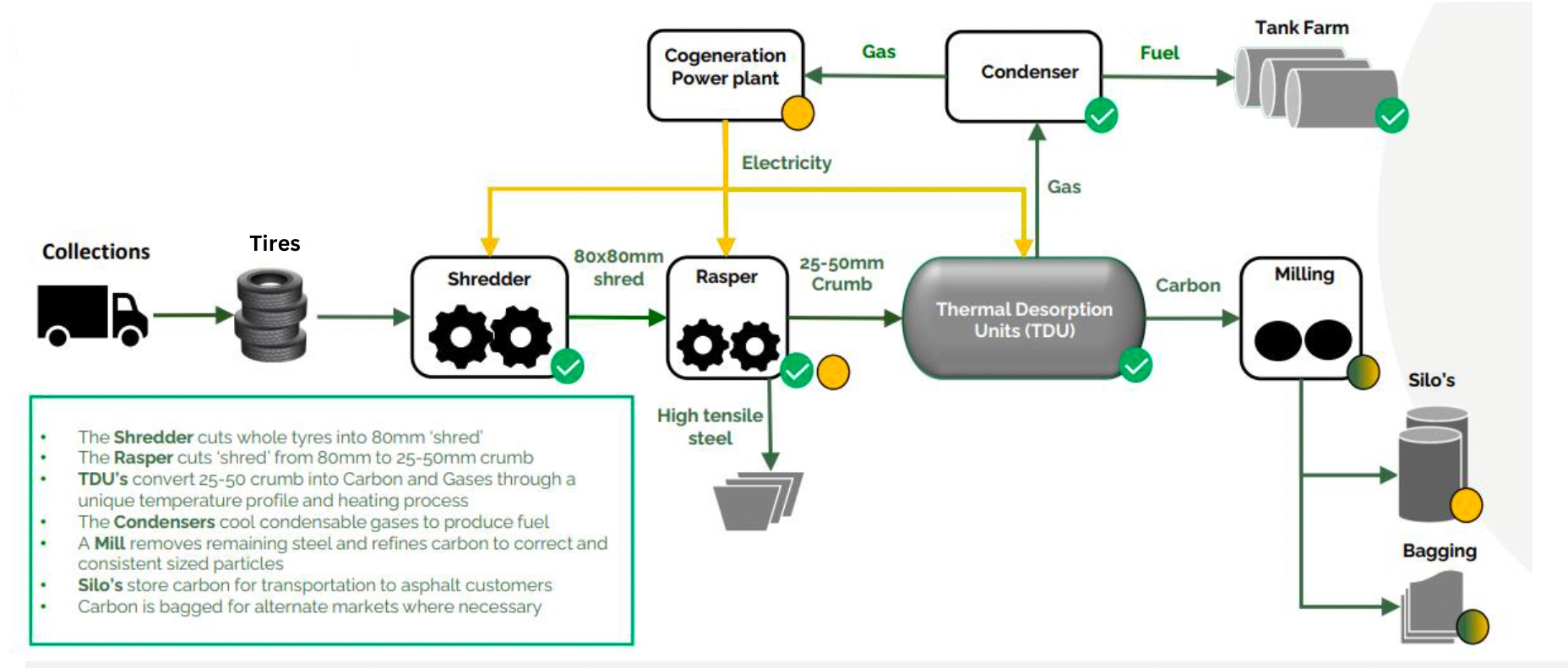

Processes

- Step 1 :- Collection of waste rubber tires

The first step is the collection of waste rubber tire that you want to recycle

- Step 2 :- Shredding of waste rubber tires

Mechanical shredding of waste rubber tire:

The mechanical system involves shredding scrap tires into smaller chips at ambient temperature. Depending on the proposed use of the recycled rubber, the waste may be cut into smaller and smaller pieces as the fiber is removed. The end product is called ‘crumb rubber’

Cryogenic shredding of waste rubber tire:

he process is called ‘cryogenic’ because the temperature here can go as low as -80 degree Celsius to -120 degree Celsius. Shredded or the whole tire is cooled to -120 degree Celsius and it becomes glass hard and brittle. It is crushed or grounded to a fine size of 50-250 mm in special mills

- Step 3 :- Sorting

It involves removing textile fibers and steel from the shredded rubber. Typically, this occurs after the shredding process. And it is done using magnets. These magnets draw out the steel fibers from the whole bunch.

- Step 4 :- Screening

The stage after separating wires from rubber is screening. The goal of screening is to observe the rubber carefully and ensure no steel is left in the rubber. You will essentially screen large volumes and sizes of rubbers with no wires and sort them according to their sizes. It also involves the elimination of any unwanted substances and reducing the sizes of large rubbers.

- Step 5 :- Cleaning

This involves a thorough cleaning of the screened rubber. Here, we use water and various cleaning agents to get the final product

- Step 6 :- Packaging & Transportation

The clean rubber derived from the cleaning stage is packed and delivered to factories that need them as raw materials for their plants. Few examples of these factories include manufacturers of rubber shoes and playground turfs.

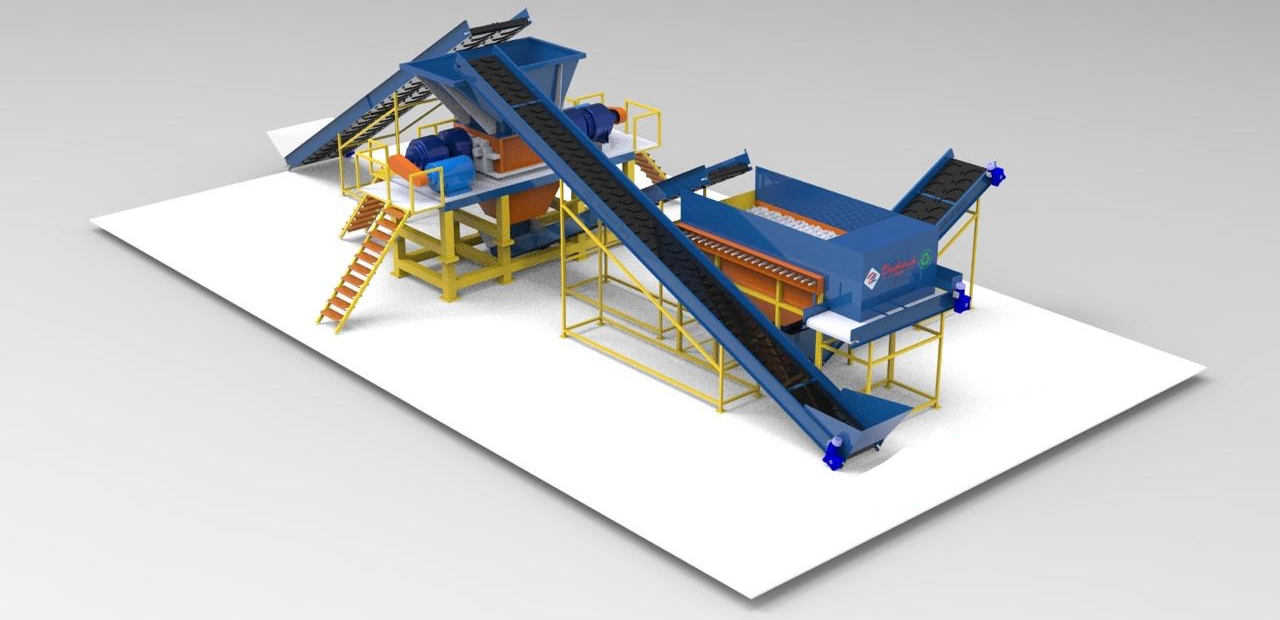

Tyre to Shreds